Whatever parts you need for your project, the Sintratec S1 brings your digital objects to reality better than ever. You can print functional parts and bring your crazy shaped design concept to life.

Hugo Arnold, Leader of Prototyping Laboratory at Geberit AG in Switzerland, talks about the key factors that convinced him to purchase a Sintratec S1.

Combined with the Sintratec PA12 Powder, the Sintratec S1 enables you to print strong, temperature resistant, precise and durable work pieces. Explore the wide range of application possibilities within additive manufacturing and rapid prototyping with the Sintratec S1.

With the help of the Sintratec Central Software you can manage your print jobs with ease. You can try it for free even before receiving your Sintratec machine. Read more

Technical Specifications

The print volume is 130 mm x 130 mm x 180 mm.

The Sintratec S1 is fully CE-certified and runs on standard 230V power connection. You can find more detailed information in the fact sheet below.

Video

Swiss Innovation

The Sintratec S1 is designed and manufactured in Switzerland. Sintratec's R&D team is always at the cutting-edge of laser sintering research. The cooperation with Switzerland's leading technology institutes allows for ground-breaking progress within the laser sintering technology. Read more

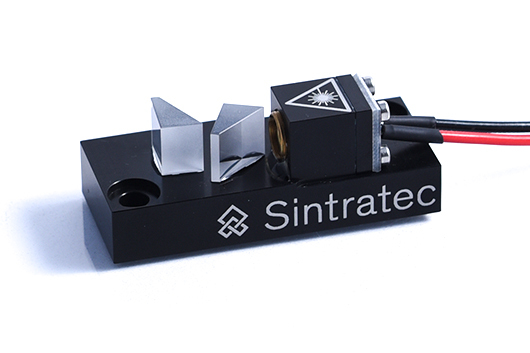

Diode Laser Sintering

Laser sintering is the gold standard in additive manufacturing. Due to Sintratec's S1 high precision diode laser you can expect exceptionally good looking printed parts. Read more

Setting up the Sintratec S1

Compared to other laser sintering equipment setting up a the Sintratec S1 does not require special on-site installations such as industrial ventilation systems, high voltage power supply or pressurised air. A standard power connection is sufficient to operate the machine. Sintratec recommends installing the printer in an environment where powder residue does not pose a problem.

Workshop in Switzerland

We support Sintratec S1 customers in building up detailed knowledge about their S1 and laser sintering. Visit us in Switzerland and attend one of our workshops. Get in touch

S1 in 3D

FAQ

Compared to stereolithography (SLA):

- Significantly more durable

- Very robust even in UV light conditions

- Freedom of form

- No additional support structures needed

- Higher thermal load

Compared to filament 3D printers (FDM):

- Significantly more durable

- Higher resolution

- Freedom of form

- No additional support structures needed

Read more: Technology

Sintratec recommends wearing a provided dust mask while handling powder.

Before you start printing with your Sintratec S1 machine, please read the safety section in the operating manual carefully.

The main print material is a high performance polyamide 12 polymer. To extend our material portfolio Sintratec is continuously researching new materials.

Visit our material section for more information.

No, the S1 does not support metal printing.

You can order print materials in the Sintratec webshop.

The Sintratec Central Software is available on Windows.

We support Windows 7 64-bit and Windows 10 64-bit.