SLS 3D printing on the fast track

The SAE Racing Team of the Munich University of Applied Sciences designs and builds its own racing car from scratch every year as part of the Formula Student racing series and participates in events all over Europe. The high demands on individually manufactured components and the material properties make 3D printing indispensable for the development of motorsport. We were able to accompany Niklas Rösler and his team at the largest Formula Student event at the Hockenheimring.

Picking up speed in your studies

The interdisciplinary team of munichmotorsport is made up of about 40 students from different faculties and disciplines of the Munich University of Applied Sciences. From automotive, electrical and mechanical engineering to business administration, design, and marketing, the team bundles its competencies to fulfill all disciplines of the Formula Student racing series. In one of the biggest engineering competitions of the world, approximately 100 teams not only compete against each other on the race track but also have to prove their skills in static disciplines such as business planning and cost calculation.

Unique rapid prototypes thanks to SLS 3D printing

Almost all the parts needed for the interior of the fully electric race car are one-offs that have to be manufactured over a short period of time. «3D printing offers the best prototyping platform for us to manufacture, our housings and brackets built into the car», explains Niklas Rösler. The engineering student was in charge of the car’s high-voltage system this year. Due to their complex geometry, many of the required components are usually impossible or very cost-intensive to realize using conventional manufacturing technologies. «SLS 3D printing is the most suitable prototyping technology for us. We can use it in almost every situation around the car», Rösler notes.

Stable and safe with PA12

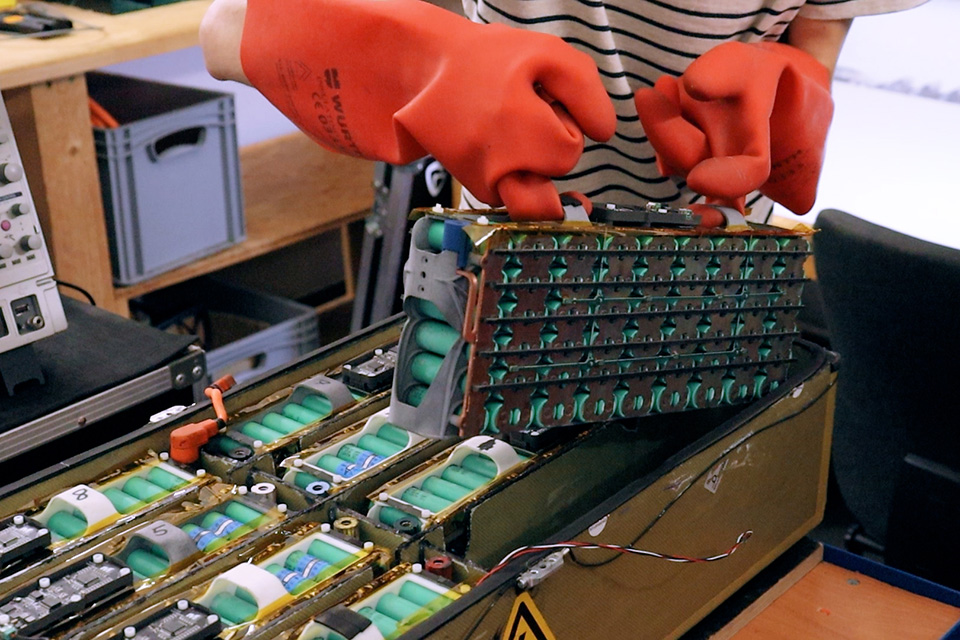

SLS 3D printing meets the requirement for almost all applications in the car. One of Rösler’s tasks was to make sure that the battery cells are well stored and that the cooling of the system is also guaranteed. To that end he developed housings which were subsequently 3D printed with PA12 and on the Sintratec S3. This component stabilizes the individual battery cells in the vehicle’s rear and ensures a firm hold during rapid load changes and three-dimensional force application. For use in electric vehicles, dielectric strength plays a very important and safety-relevant role. For cooling the entire system, spacers, also made of PA12, are used to regulate the airflow. «The PA12 material from Sintratec covers most areas of application in the race car. It offers the best mechanical properties for our purposes and high dielectric strength», Rösler says.

3D printed components for the high-voltage system made with PA12.

Constant potential for improvement

The race weekend of the Formula Student main event was visibly exhausting for Niklas Rösler and his team, but successful. After initial technical problems, the team achieved a good run in the autocross and also scored plenty of points in the static disciplines. In the overall standings, the team secured 20th place out of 71 participating teams in the electric class. «We are very proud of the performance and the design of the car, and above all, of what we have achieved and accomplished as a team in the past year,» Rösler sums up. He and his team are sure to rely on 3D printing again next year.

“SLS 3D printing is the most suitable prototyping technology for our racing team. We can use it in almost every situation around the car.”

Niklas Rösler

Prototyping Technician

munichmotorsport

Need consulting?

Our team is happy to advise you and to begin your journey into the world of SLS. Contact us right away!