Sintratec S2

More than just a 3D printer

The Sintratec S2 has proven itself in the field as a reliable, industrial 3D printer. With a precise fiber laser and a sophisticated heating system, the Fusion Module ensures repeatability and consistent printing results.

Technical Specifications

With the S2 you can print high-quality parts and prototypes with exceptional properties and accuracy within a short amount of time.

Laser Type

1,490 × 990 × 600 mm

Laser Spot Size (FWHM)

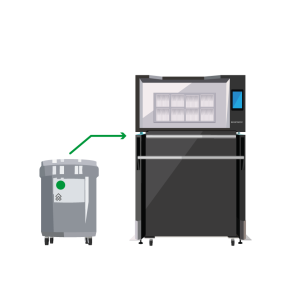

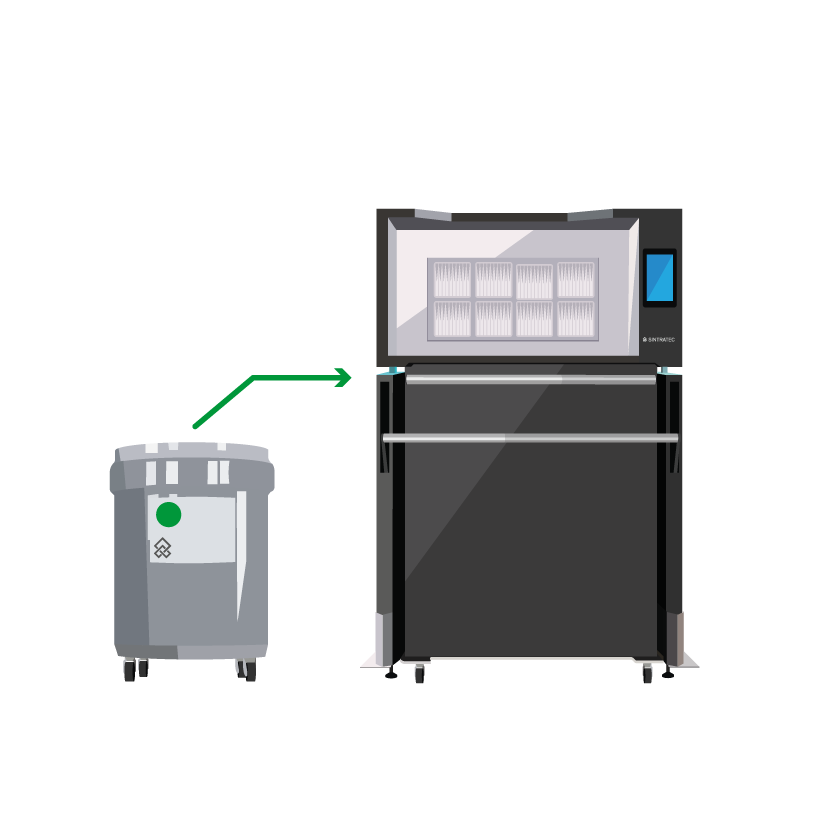

Build Modules

Expand your 3D printing fleet with multiple Build Modules dedicated to different materials

to reduce downtimes and achieve a next-level throughput.

Need a lot of parts? The MCU-220 features a 90% larger print volume than its predecessor. The Build Module is compatible with all AMP Modules and built to meet the demands of industrial manufacturing.

400 mm*

Build cylinder volume

65 kg

Need flexibility? The MCU-160 is our entry-level Build Module and ideally suited for the production of small to mid-sized series. As part of the AMP range, the core unit is backward and forward compatible.

400 mm*

Build cylinder volume

65 kg

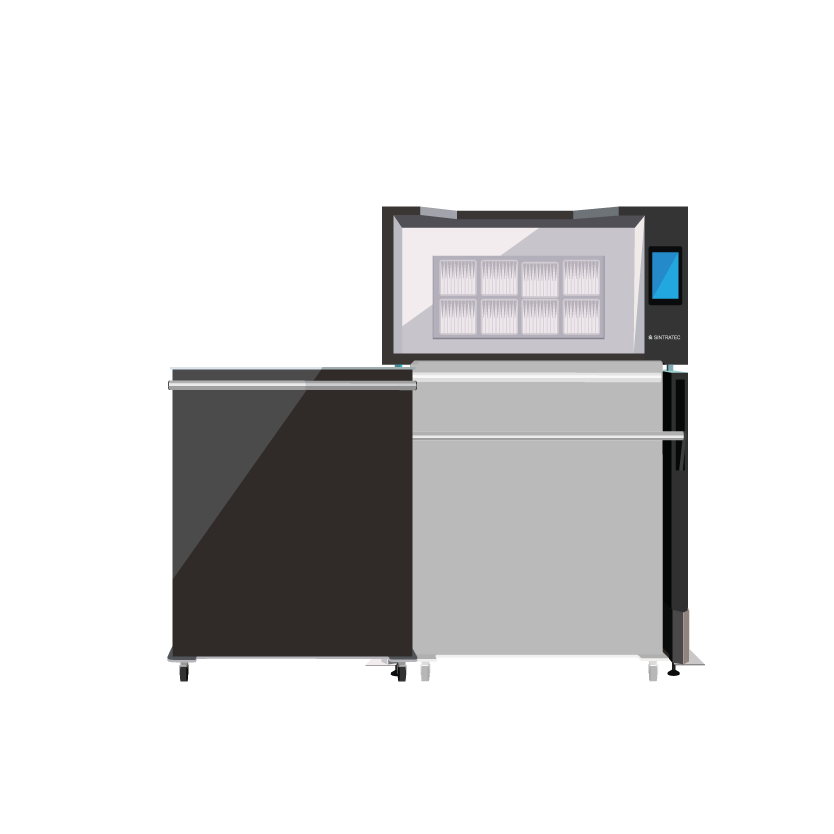

How does our SLS process work?

Fusion Module

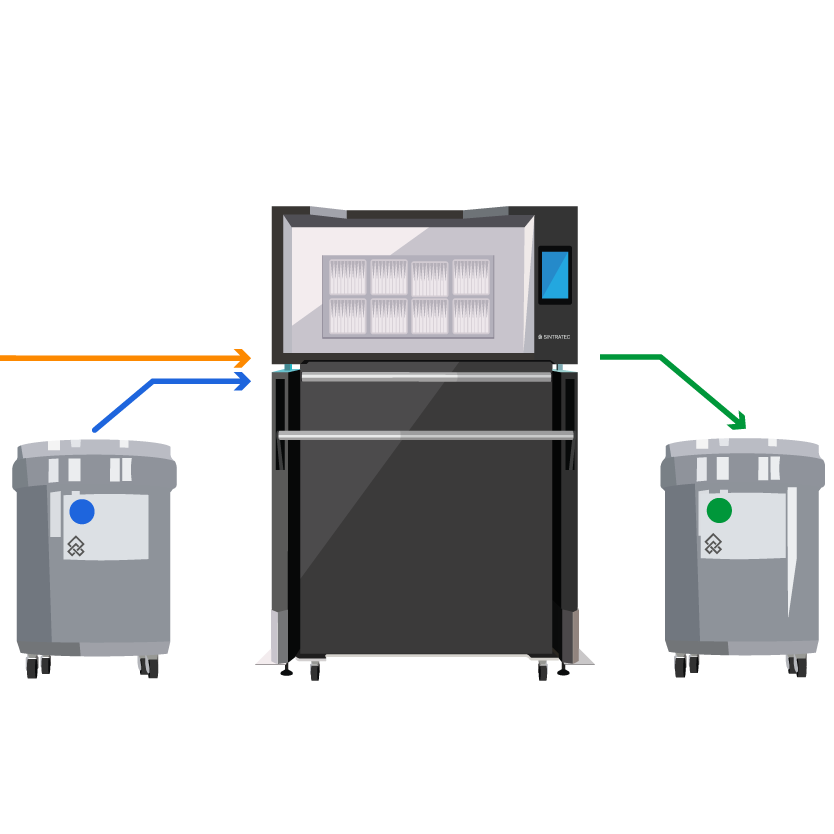

Material Handling Modules

For cleaning and preparing, we offer additional material handling solutions that are

designed to work seamlessly with all Build Modules.

After printing, simply move your Build Module into the dedicated Material Handling Station. In the MHS, you can then easily depowder your objects with a vacuum cleaner and maintain clear visibility thanks to an air filtration system.

Materials

Our current material portfolio:

We are continuously working on bringing new SLS materials to the All-Material Platform.

Get an individual offer!

Ready for the future of manufacturing? Request your quote today!