Why are SLS 3D printers suitable for small businesses?

When it comes to Selective Laser Sintering (SLS), there are often barriers that prevent companies and users from venturing into this technology. In this article, we want to showcase the benefits of SLS and why this 3D printing process can be especially suitable for small businesses.

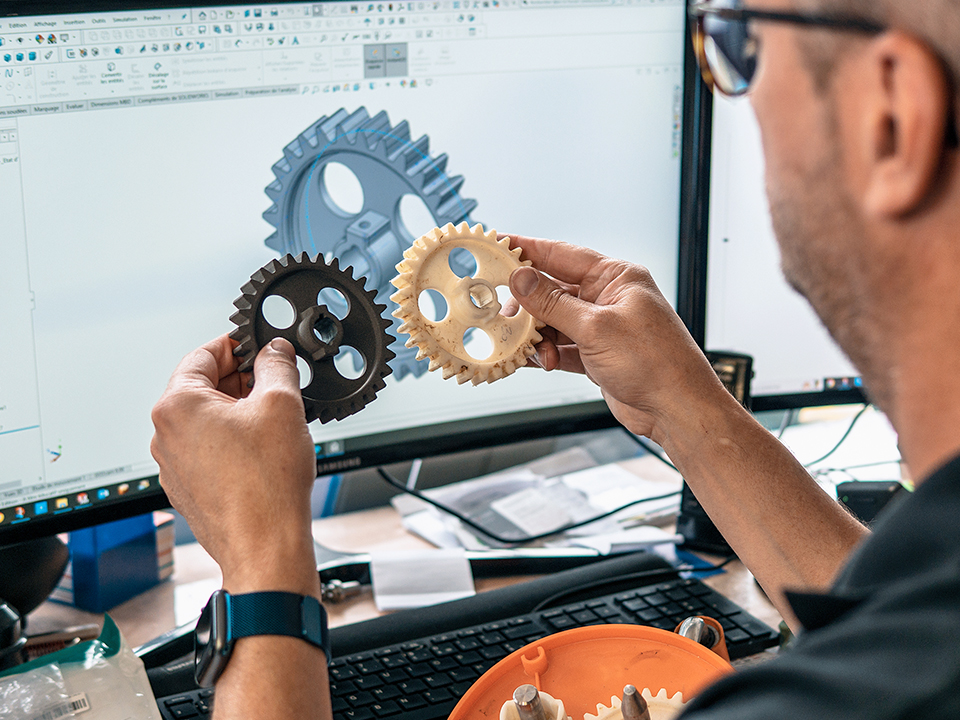

What is SLS (Selective Laser Sintering)

If you are not a 3D printing expert by now, there are a few things to mention when it comes to Selective Laser Sintering (SLS). SLS is a 3D printing technology that uses a laser to selectively fuse or sinter powdered materials, typically thermoplastics such as nylon, elastomer, or polypropylene, into a solid object layer by layer. It can also work with composite materials like metal-filled or glass-filled polymers or metals. We covered the SLS process in great detail in another article.

SLS compared to other technologies

In contrast, other 3D printing technologies like FDM (Fused Deposition Modeling) or SLA (Stereolithography) use different approaches, such as extruding molten material or curing liquid resin with light, to create objects. These technologies may have limitations in terms of the types of materials they can use. Another benefit SLS provides is the fact that you don’t need support structures during the printing process because the unsintered powder acts as a self-supporting medium. This eliminates the need for additional support material that needs to be removed later, as is the case with other technologies like FDM or SLA.

SLS just for big companies?

When talking about SLS it is always about the high cost and the large size of the printers. However, manufacturers like Sintratec offer professional small to medium-sized machines at a much more affordable price range. The systems are designed for rapid prototyping and permit fast iterations in the development process without relying on external manufacturers. This speeds up the product development cycle, reduces lead times, and allows for faster testing and refinement of ideas.

What makes SLS economical

Compared to traditional manufacturing processes, more compact SLS printers can be cost-effective for small businesses. It eliminates the need for expensive molds or tooling, reducing upfront costs. Additionally, producing parts on demand reduces inventory costs and minimizes waste, as only the required amount of material for the parts is used with up to 90% being recyclable (depending on the material).

Flexibility for your production

SLS 3D printers are not limited to prototyping - they can also be an interesting option for small-scale production runs. This is especially beneficial for print service bureaus that require low-volume manufacturing, and businesses that offer customized or niche products, as well as just-in-time production. By having an SLS machine in-house, you can significantly reduce lead times for manufacturing. You will gain more control over your designs, minimizing the risk of information leakage, increasing control over the production process, and being able to respond quickly to customer demands or market changes.

Empowering Small Businesses

It’s important to note that SLS 3D printers typically require a higher initial investment compared to other types of 3D printers, and there may be ongoing costs associated with materials, maintenance, and machine operation. However, considering the advantages mentioned above, an SLS 3D system can be a valuable asset for your business seeking to enhance its manufacturing capabilities and stay competitive in today’s market.

Exemplary return on investment calculation

With modular and scalable systems like the Sintratec All-Material Platform, companies can not only future-proof their setups but also effectively tailor manufacturing to their needs.

3D Model

Digital STL file designed

in a CAD software

Print Job

Imported model replicated 550 times

and nested in the print volume

3D Print

3D printed parts are used as stoppers

inside Sintratec Build Modules

Type of part

Print material

Amount of parts

System occupation

Stopper

PA12

550 parts

21 hrs 23 min

External cost per part*

Sintratec S2 cost per part

External cost per run*

Sintratec S2 cost per run

Estimated machine refund after

6.19 EUR

0.89 EUR

3404.50 EUR

489.90 EUR

12 runs / 10.7 days

Type of part

Stopper

Print material

PA12

Amount of parts

550 parts

System occupation

21 hrs 23 min

External cost per part*

6.19 EUR

Sintratec S2 cost per part

0.89 EUR

External cost per run*

3404.50 EUR

Sintratec S2 cost per run

489.90 EUR

Estimated machine refund after

12 runs / 10.7 days

*Based on average service bureau pricing

Need consulting?

Our team is happy to advise you and to begin your journey into the world of SLS. Contact us right away!