Faster treatment with 3D printed orthoses

Australian company Advanced Family & Sports Podiatry manufactures customized foot orthoses on the Sintratec S2 system. The 3D printer’s production capabilities allow Mark Ireland and his team to provide a timely and individualized treatment to their patients.

A state-of-the-art practice

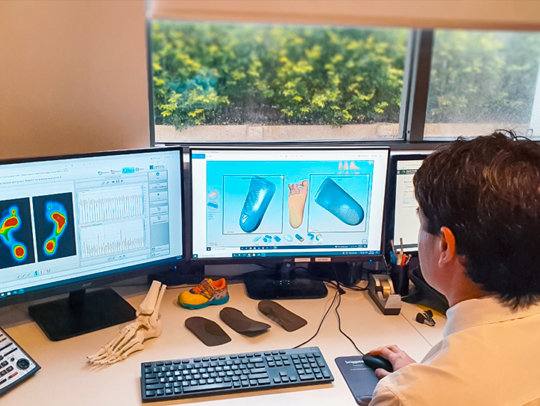

Mark Ireland is the owner and principal podiatrist at Advanced Family & Sports Podiatry, an Australian company that was founded from scratch in 2006 as a one-person practice. Today, him and his team of 10 people work hard on the vision, that has not changed since then: «We want to provide clients with sports injuries a state-of-the-art practice with the most modern equipment to improve their lower limb, foot and ankle health», says Mark. To that end, the podiatrists at AFSP have also begun to incorporate modern additive technologies into their work process.

Experimenting with 3D methods

Complex shapes for the human body

More design freedom with SLS

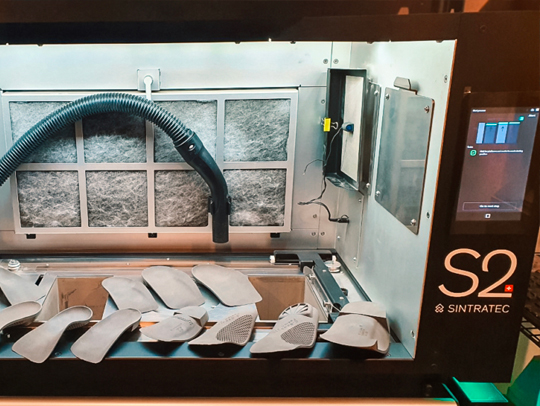

In April 2021 Advanced Family & Sports Podiatry acquired a Sintratec S2 system. And soon after, the full potential of the SLS technology became evident: «The biggest advantage to us is the speed of production, accuracy of the build, unrestricted design freedom to test and push new shapes for the benefit of our clients», Mark emphasizes. Ever since the system was commissioned in the Australian practice, the ASFP podiatrists has been using the Sintratec S2 to produce custom and semi-customized foot orthoses with durable Sintratec PA12 nylon material. Whereas patients previously had to wait up to two weeks for their orthoses, they are now able to receive a customized product within 24 hours thanks to SLS.

A promising future for patients

“In podiatry we require high dimensional accuracy, resistance to deformation and heat, and ability to elongate without shattering. The Sintratec technology does all of the above easily.”

Mark Ireland

Owner & Principal Podiatrist

Advanced Family & Sports Podiatry AFSP